Just as important as the type of wood used for kitchen cabinets is the quality of its construction. It is generally accepted that plywood is superior to the common cabinet material alternative, particleboard. What are the telltale signs of construction that set the higher end apart from the flimsy generic?

How To Recognize Quality Construction

Let’s examine the characteristics of cabinet box and drawer construction, which determine what promises a lifetime of trouble-free usage.

First, let’s inspect the box itself. The number of variables in its construction can be maddening, so we’ll focus on the basics.

It doesn’t matter what material you’re dealing with – particleboard or plywood – the ends of the box need to be at least 1/2 to 3/4 inches for them to be of good quality construction.

It’s probably obvious that the thicker they are, the more sturdy the structure will be.

It’s ok for the back of the box to be thinner, between 1/4 and 1/2 inches thick because it will be made of the same good stock as the sides.

You can tell a really cheap product back if it is something like 1/8 inch fiberboard and stapled to the rear.

A backless cabinet isn’t worth consideration as it’s either damaged or flimsy. Most of our cabinet boxes are made of 5/8″ plywood and feature a full back.

Handling the drawers underneath will give you a good idea of their quality.

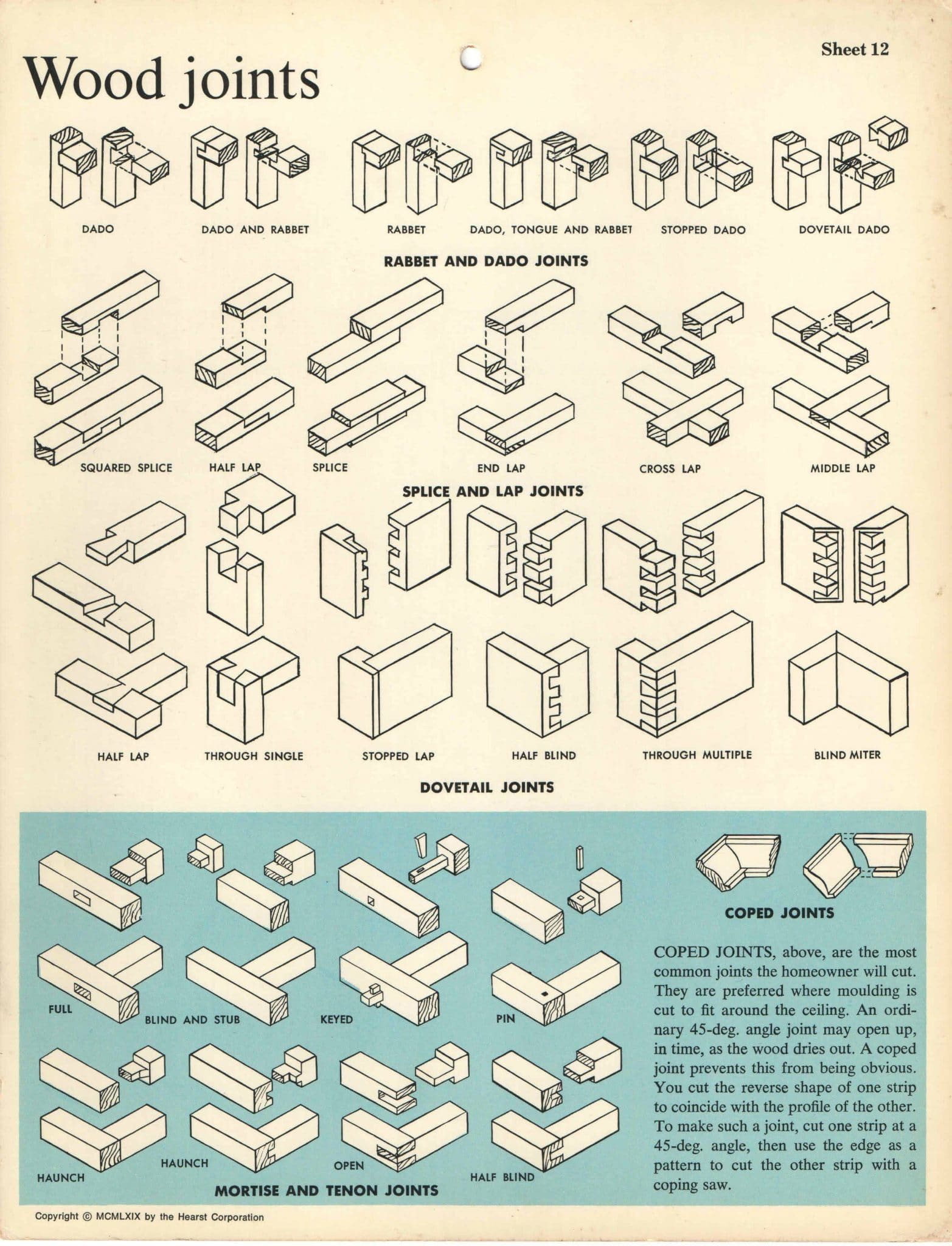

Time was you would do your best by getting all-wooden drawers assembled with dovetail joints. Now, they’re of an almost bygone era.

With advances in related technology, impossibly strong glues have made joints such as the dowels, biscuits, and dado’s just as reliably solid as the classic dovetails.

Even in the higher end cabinets, they have recently been forgone for new alternative joints. Oddly enough, dovetailed joints appear more than ever in generic, mass-produced cabinetry, like those you’d find from big box stores.

Despite the effective options and without doubt, the original dovetail joint is still the strongest.

Often, an alternative is chosen for cosmetic reasons. A manufacturer may rely on a style that conceals the joints entirely.

As alluded to previously, some dovetails are better than others. They are intended to fit firmly, locking together without gaps between the edges.

It doesn’t matter if it’s a dovetail, dowel, biscuit or groove, they all work on the same interlocking concept.

Now that you have a better idea of what it takes to hold a cabinet together firmly, you can probably guess that it would be in your better interest to stay clear of simple butt joints that merely use staples and/or glue.

Remember, the drawer box should always be made of strong wood between 1/2 and 3/4 inches thick. Avoid ones made of cheap particleboard that is only a quarter inch thick and uses glue and stapled joints.

The drawer is never supposed to sag under a heavy load. It needs to be sturdy. The bottom of the drawer should be dado’d on all sides, not just stapled to them.

Obviously, your wood selection will affect the cabinet you choose, but almost just as importantly is the method of construction applied. Quality wood and sturdy assembly will give you a fine furniture product designed to last a lifetime.