When you think of furniture, cabinets, and lumber, you probably think about wood.

If you are familiar with the furniture and cabinet industry, you probably think about woods like maple, oak, walnut, mahogany, or birch.

These are the common hardwoods that are usually used in making quality cabinets and other woodworking forms.

Seemingly out of nowhere, a new contender has arrived. Rubberwood, the wood we get from rubber trees, is being used increasingly for cabinets and various other surprising products.

Rubber Trees: A History

Rubber trees, Hevea Brasiliensis, were originally found in and around the Amazon basin. The rubber produced from the rubber tree was introduced to Europeans in a very simple form as they explored the American continents in the 1500s.

In the 1700s, it was brought back to England and other European countries as an eraser product. But all of that was just the beginning.

By the 1800s, rubber products exploded into popularity with many new uses. Rubber was used for things like shoe soles and rubber tubing, but the big game changer was rubber tires.

Talk about reinventing the wheel. Think about all the hundreds of things you see on a daily basis that have wheels.

Before rubber, these wheels would have been made from wood or some other less desirable material. Even to this day, we generate seemingly endless demand for rubber products, such as latex gloves, condoms, car tires, and fitness balls.

The Origin

Don’t get the wrong idea about all this rubber that is being produced. Some people will point their finger at any tree-related product and scream about “Deforestation!”

In reality, like with paper products, the trees used to harvest rubber materials are mostly grown on farms. Most of these rubber tree farms, where most of our rubber is produced, are in Southeast Asia.

The Process

Seemingly endless rows of rubber trees are drilled and tapped similarly to get maple extract from maple trees. The milky white liquid is collected in buckets and then used to produce all kinds of useful rubber products that improve our lives.

Finally, after all the useful rubber liquid has been drained from the tree, you are left with a tree that needs to be disposed of.

In a wonderful stroke of eco-friendly thinking, cabinet companies have started to repurpose rubber tree wood for cabinets. Rubber tree wood is a hardwood.

With a Janka rating of around 995 pounds, rubberwood holds up well to abuse and impact. It’s about as hard as Cherry but not as hard as Oak. Rubber tree wood costs less than you would expect to pay for fancy hardwoods like walnut or cherry.

Rubberwood takes stain very well, so creating beautiful cabinets with walnut, maple, mahogany, ebony, or cherry is not hard.

All kinds of wood experience shrinkage and expansion with major changes in heat and humidity. Perhaps rubberwood’s best feature is that it doesn’t suffer from shrinkage as much as other kinds of wood. With so many positive features, it is a wonder that more cabinets are not made from rubber wood.

Cabinet Products

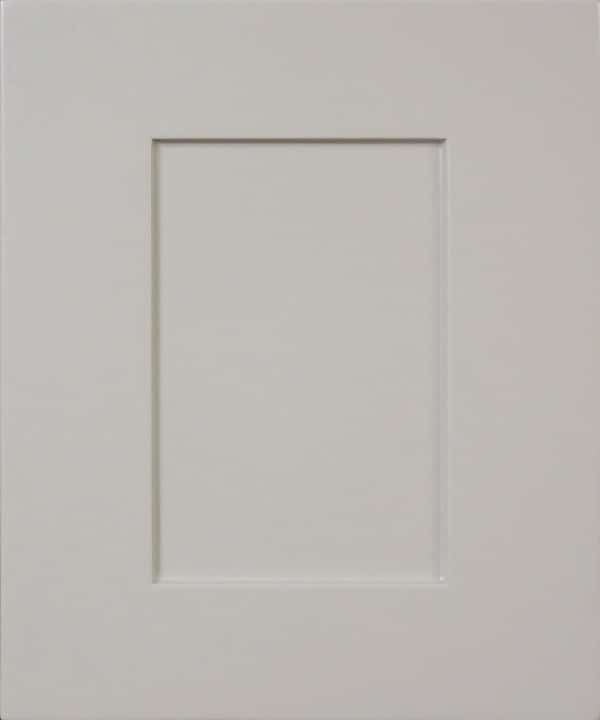

Rubberwood can be used to make several traditional cabinets, such as shaker-style cabinets with solid slabs of rubberwood.

Our cabinets use rubberwood’s stability and resistance to shrinking and warping. The doors are made from a single solid piece of rubberwood.

This technique prevents the consistent cracking and chipping of paint on and around the corners of the doors where the frame pieces meet.

Other Rubberwood Products

It’s not just cabinet companies that are making use of rubberwood. Cutlery companies also use rubber tree wood for their knife blocks.

Many people’s kitchen knives consist of a small chef knife, a bread knife, and some steak knives they bought at Target.

These knives usually end up in a drawer somewhere in their kitchen. There is nothing inherently wrong with storing your cutlery this way, but this is just not preferable for many people.

I previously wrote a little about storing cutlery in Creative Kitchen Storage, where I said something to the effect of: A beautiful countertop knife block is the best way to show off that exceedingly expensive cutlery set you are still making payments on.

Knife blocks are often made of oak, cherry, bamboo, or walnut and are surprisingly expensive.

Just like cabinet companies, cutlery companies can save money by using reclaimed rubber tree wood. This wood works well for knife blocks, looks great, and allows the cutlery company to pass the savings on to the consumer.

If cutlery companies are using rubberwood to make knife blocks, you probably already guessed that rubberwood is also used for cutting boards and butcher blocks.

Many of the rubberwood’s qualities make it a good choice for knife blocks and wooden cutting boards.

Conclusion

Rubberwood may not have the name recognition of other hardwoods, but it is a great choice. Small kitchen devices like cutting boards, knife blocks, and butcher blocks have all been made from rubberwood with great success.

The real significant use of rubberwood will probably continue to be in the hardwood doors and frames of kitchen cabinets. It is possible that in the future, another low-cost hardwood option will present itself, but if you are looking for premium quality cabinets without the premium price tag, Rubberwood RTA cabinets are the way to go.